UV absorber UV-571 (liquid)

Product Category:

Jiangxi Kerun New Materials Technology Co., Ltd. is a privately-owned shareholding enterprise. It is an enterprise established in accordance with the new organizational form and modern management concepts of enterprises, integrating the research, production, and sales of ultraviolet absorber-type polymerization aids, with a total area of 100 mu.

Keywords: ultraviolet absorber type polymerization aid

Product details

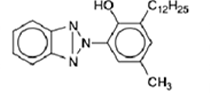

1. Product Name: UV Absorber UV-571

2. Molecular Structure Formula:

3. Molecular Weight: 393.56

4. CAS NO: 125304-04-3

5. Physicochemical Properties: UV-571 is a yellow, transparent, viscous liquid benzotriazole UV absorber that imparts good light stability to various polymers. It is easily soluble in many solvents, monomers, or intermediates, and easily emulsifies in water-based adhesives. UV absorber UV-571 is characterized by high compatibility with various substrates, low volatility even at high temperatures, and high absorption and protection efficiency.

6. Characteristics and Applications: UV absorber UV-571 is widely used in thermoplastic PUR coatings and integral foam plastics, rigid plasticized polyvinyl chloride, PVBMMA, PVDC, EVOH, EVA, high-temperature curing unsaturated polyesters, and as a spinning aid in PA, PET, PUR, and PP fibers. UV absorber UV-571 is also suitable for latex wax adhesives, styrene homopolymers and copolymers, elastomers, and polyolefins. The dosage of UV absorber UV-571 ranges from 0.2% to 50%, depending on the substrate and performance requirements. In polyimides, the dosage ranges from 0.2% to 0.5%, depending on the substrate, processing conditions, and requirements for long-term light stability. In polyvinyl chloride, the dosage ranges from 0.3% to 0.5%; in composite polyvinyl chloride, the concentration can reach 5%. In adhesives, the dosage ranges from 0.5% to 1.0%. UV absorber UV-571 can be used in combination with other additives such as phenolic antioxidants, auxiliary aids (phosphites, thioethers, etc.), UV absorbers, and hindered amine light stabilizers (HALS).

Our company has one domestic four-roll rolling mill, one imported Sennimill twenty-roll rolling mill, two cleaning lines, three continuous annealing lines, two straightening lines, and one slitting line. Each production line is in the process of continuous supplementation and replacement. The company's main products are titanium and titanium alloy foils with a thickness of 0.03~0.5mm, and 200, 300, and 400 series stainless steel foils with a thickness of 0.03~0.35mm. The company also researches and produces special alloy foils such as Hastelloy, soft magnetic alloys, copper-based alloys, and iron-chromium-aluminum. The company's products use industry-leading raw materials and have advanced process technology. The produced foil strips have good plate shape, small tolerances, and excellent performance. At the same time, they can meet customers' needs for special surfaces, special hardness, and special mechanical properties.

Ningbo Zhongtai adheres to the headquarters' tenet of "Quality is Dignity, Innovation is Life," and insists on customer-centricity. Since its establishment, the company's product quality has been stable and has been consistently praised by customers. The company's products are widely used in information and communication, high-end electronics, new energy, kitchenware, building decoration, petrochemicals, auto parts, and medical fields.

Product Application

Online Message